Laminated busbar-highway for power distribution system

Tiempo de liberación:

Jan 26,2021

Sichuan Difu Electric Co., Ltd. is a wholly-owned subsidiary of Sichuan Difu Technology Group (the registered capital of the group company is 50 million RMB), with a registered capital of 4.6 million RMB, located in Luojiang District, Deyang, Sichuan. The company is committed to the research and development, production and sales of various customized copper and aluminum material laminated busbar, soft connection, soft busbar and other electrical components. Complete solutions for all types of power distribution systems.

Sichuan Difu Electric Co., Ltd. is a wholly-owned subsidiary of Sichuan Difu Technology Group (the registered capital of the group company is 50 million RMB), with a registered capital of 4.6 million RMB, located in Luojiang District, Deyang, Sichuan. The company is committed to the research and development, production and sales of various customized copper and aluminum material laminated busbar, soft connection, soft busbar and other electrical components. Complete solutions for all types of power distribution systems.

1) Laminated busbar

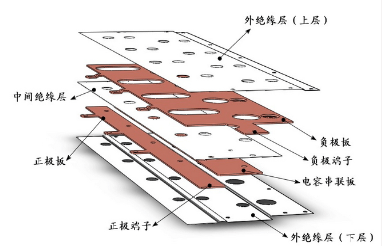

Laminated bus bar is also called composite bus bar, laminated non-inductive bus bar, laminated bus bar, sandwich bus bar, low-inductive bus bar, electronic bus bar, laminated bus bar, etc. It is a multi-layer composite structure connection circuit formed by superimposing multi-layer conductive materials and insulating materials. It is a multi-layer composite structure connection row. Compared with traditional heavy and messy wiring methods, it has the characteristics of low impedance, anti-interference, good reliability, space saving and quick assembly. Widely used in rail transit, wind and solar inverters, industrial inverters, large UPS systems or other components that require power distribution.

2) Performance index of laminated busbar

3) Product features

A. Inductance coefficient, compact structure, effectively saving internal installation space, increasing heat dissipation area, and effectively controlling system temperature rise;

B, the minimum impedance, reduce the line loss, so that the circuit's large current carrying capacity has been greatly improved;

C, reduce the voltage commutation process spike damage to components, extend (improve) the service life of electronic components;

D, reduce system noise and electromagnetic interference, radio frequency interference;

E. High-power modular connection structure components with simple and quick assembly.

4) Application collar

A. Power electronics field

I. Industrial frequency converter;

II. New energy field [wind energy, solar energy, thermal power inverter (converter)]];

Ⅲ. UPS system, high density distribution box;

IV. Base stations, telephone switching systems, large network equipment, etc;

B. transportation

I. Rail train;

II. Electric vehicles;

III. Engineering vehicle

IV. Transportation charging pile;

C. military field

(a) submarines;

II. Warships;

III. Armored vehicles;

IV. Aircraft carriers;

D. aerospace field

I. Aircraft;

The Space Shuttle;

Ⅲ. Receiving radar system;

IV. Missile systems;

Palabras clave:

Previous

Previous

Hot News

The Ins and Outs of Busbars: Powering Our World

Discover the fascinating world of busbars, their functions, and applications in electrical systems.

Nov 05,2025

Understanding Busbars: The Backbone of Electrical Systems

Dive into the world of busbars, their significance, and how they power our electrical systems.

Oct 31,2025